Excessive moisture within the pavement base just before applying the bituminous surface is a frequently observed factor contributing to the premature deterioration of newly-built unbound pavements. Managing the moisture levels in pavements during construction can mitigate potential damage to the pavement and preserve the community benefits once the road becomes operational.

This article discusses the role of the Degree of Saturation (DOS), how it is determined, and corrects some common misconceptions. It is discussed in relevance to the Queensland DTMR Technical Specifications.

What is DOS?

DOS is an acronym for Degree of Saturation. It is not a direct measurement of moisture content, it is a measurement of how many air voids within the pavement are filled with water. It is important to remember that DOS is not entirely dependent on moisture content, as dry density heavily affects the number of voids available to hold water. It is not a physical test method on its own, it is a calculation that uses data from other test methods. This method is only applicable to layers of pavements consisting of unbound materials.

What methods are required for DOS?

There are three values that are needed for the DOS calculation. Insitu moisture content (%), compacted dry density (tm^3), and soil particle density (tm^3).

To determine the insitu moisture content and compacted dry density, it must be done in accordance ‘Q141A Compacted density of soils and crushed rock – nuclear gauge’ preferably. But to use Q141A a material wet density and a material moisture bias must be set up in accordance with the nuclear gauge testing manual. If a bias has not been setup then ‘Q141B Compacted density of soils and crushed rock – sand replacement’ must be performed to determine those values.

To determine the soil particle density, it must be done in accordance with ‘AS1289.3.5.1 Determination of the soil particle density of a soil.’ This test method determines the soil particle density by calculating a weighted average of the particle density in relation to the coarse component +2.36mm sieve, and the fines component -2.36mm sieve.

The frequency upon which soil particle density is determined depends on the situation. Where an assigned maximum dry density is applicable, it must be sampled after the supply of every 10,000 tonnes, if it has not been used for more than two months, or if it hasn’t been used on the project being tested. If one-for-one testing is being performed and no assigned maximum dry density is applicable, then 1 soil particle density must be sampled per lot.

How is DOS calculated?

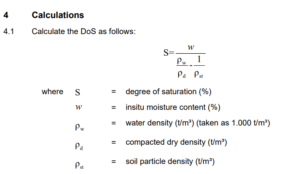

The calculation for DOS is as follows;

DOS= Insitu moisture content % / ((density of water 1.00tm^3/compacted dry density tm^3)-(1 / soil particle density tm^3))

What timeframes are involved when determining DOS?

To set up the data from scratch can be a lengthy process. To ensure that there is minimal disturbance to construction workflows, timeframes, and processes, the testing laboratory needs to sample the soil particle density and assigned maximum dry density at least one week before the material is going to be used on the project.

The assigned maximum dry density is not required for DOS but is required for ‘Q140A Relative compaction of soils and crushed rock’ which is another requirement for the conformance of unbound pavement lots. Sampling the soil particle density and assigned maximum dry density at the same time from the same stockpile also assists with minimising disturbance to construction workflows, timeframes, and processes.

Once the soil particle density has been determined, and the first lot of material has been placed, the ideal scenario is to set up a material wet density and moisture bias so that we can perform nuclear gauge tests instead of sand replacement tests. To set up the bias we need to perform six nuclear gauge tests side by side with six sand replacement tests. This will produce an average bias for both density and moisture content, the turnaround time for a bias is the next day. Once a bias has been established, we can calculate the results as soon as all the data has been entered. This is why it is preferable to set up the bias instead of performing sand replacement tests as with sand replacements you can’t get a result until the next day.

When is retesting of non-conforming lots required?

If the DOS does not conform, then we must redo the field density. If a bias has been set up and we are using a nuclear gauge it has no impact as it is just performing a nuclear field density test. If we have done sand replacements we cannot just sample another moisture content using the old wet density, as the density has changed as the material has dried out. In this case, we need to do the whole process again.

Why is the DOS important?

Degree of Saturation was developed internally by the Queensland Department of Transport and Main Roads to combat pavement movement in unbound pavements. It works on the principle of ensuring that only a certain percentage of air voids within a pavement are filled with water.

This is important because if a pavement has all of its voids filled with water its structure is then dependent on water, consequently, when pressure is applied it will move around because it is acting as though it is in a fluid state. If the voids are only partially filled with water the structure of the pavement is then dependent on solid particles interlocking and being in contact with each other, meaning that the pavement will act in a solid state when pressure is applied and not move around.

Does your next project require testing in accordance with Queensland Department of Transport and Main Roads? Our team possess extensive knowledge and experience testing in accordance with Qld DTMR Technical Specifications. We are able to advise and assist accordingly to help ensure your next project runs smoothly. Contact our team on 1300 295 835 or request a quote here.